Breadcrumb Home Update for Nut Island Headworks Odor Control and HVAC Improvements Project (Contract 7548)

Update for Nut Island Headworks Odor Control and HVAC Improvements Project (Contract 7548) Address

Nut Island facility

Exterior view of Odor Control roof and site

About this Project The Nut Island Headworks Odor Control and HVAC Systems Improvements project involves an extensive rehabilitation of the facility that will ensure that Nut Island continues to work as designed. Odor Control facility access, fuel tank replacement and other appurtenances will be rehabilitated. This project will take approximately 36 months to complete.In January 2020, this $187,410.85 contract was awarded to Walsh Construction.

The first phase of work will begin on Tuesday, April 21, 2020. The work involves the installation of erosion controls (silt fencing and straw waddles), catch basin inlet protection, tree protection, temporary chain link fence and concrete barriers delineating work zones. The initial work will be followed by establishing a temporary construction laydown area. Once these activities are complete, the next phase of work will begin in May at the Nut Island facility.

Public Access Plan Public Access paths will remain open during construction. Please obey all posted signage on site.

Contact If you have any questions please contact MWRA Public Affairs.

Updates Sign up for electronic project notifications and updates through our Everbridge service .

July 11, 2023 Perforated Pipe and Crushed Stone Trench Drain

Roof waterproofing transition

Carbon Adsorber (CAD) 2 Fiber Reinforced Plastic (FRP) 90 degree elbow

Parking lot mill and overlay

Previous 1 of Next Loading Carbon into new Carbon Adsorber Unit (CAD) System

Odor Control Roof Panel Placement

Odor Control Roof Surfacing

Odor Control Roof Insulation

Stair 12 near bench shaft

Sidewalk Repair adjacent to Emergency Spillway

Previous 1 of Next Layout of all CAD (Carbon Adsorber) vessels

Catwalk access to wet scrubbers and dampers

Screening Room Odor Control Fiber Reinforced Plastic (FRP) Replacement

Previous 1 of Next Fiber Reinforced Plastic (FRP) duct

Carbon Adsorber Inlet and Outlet Ducts

Carbon Adsorber Power and Controls

Generator Room Air Handling Unit (AHU) replacement

Previous 1 of Next All carbon vessels delivered and being set in place

CAD #9 & 10 Inlet and Outlet ducts

CAD #1 and 2 topping slab

Odor control roofing to resume in the spring

FRP Duct and grease filters in grit room

Previous 1 of Next CAD foundations and topping slab

Previous 1 of Next CAD area topping slab demolition to build new foundation

Previous 1 of Next Masonry work has begun on Stair 12 super structure

The wet scrubber testing (pH & ORP probes)

Supply air duct in Odor Control Room

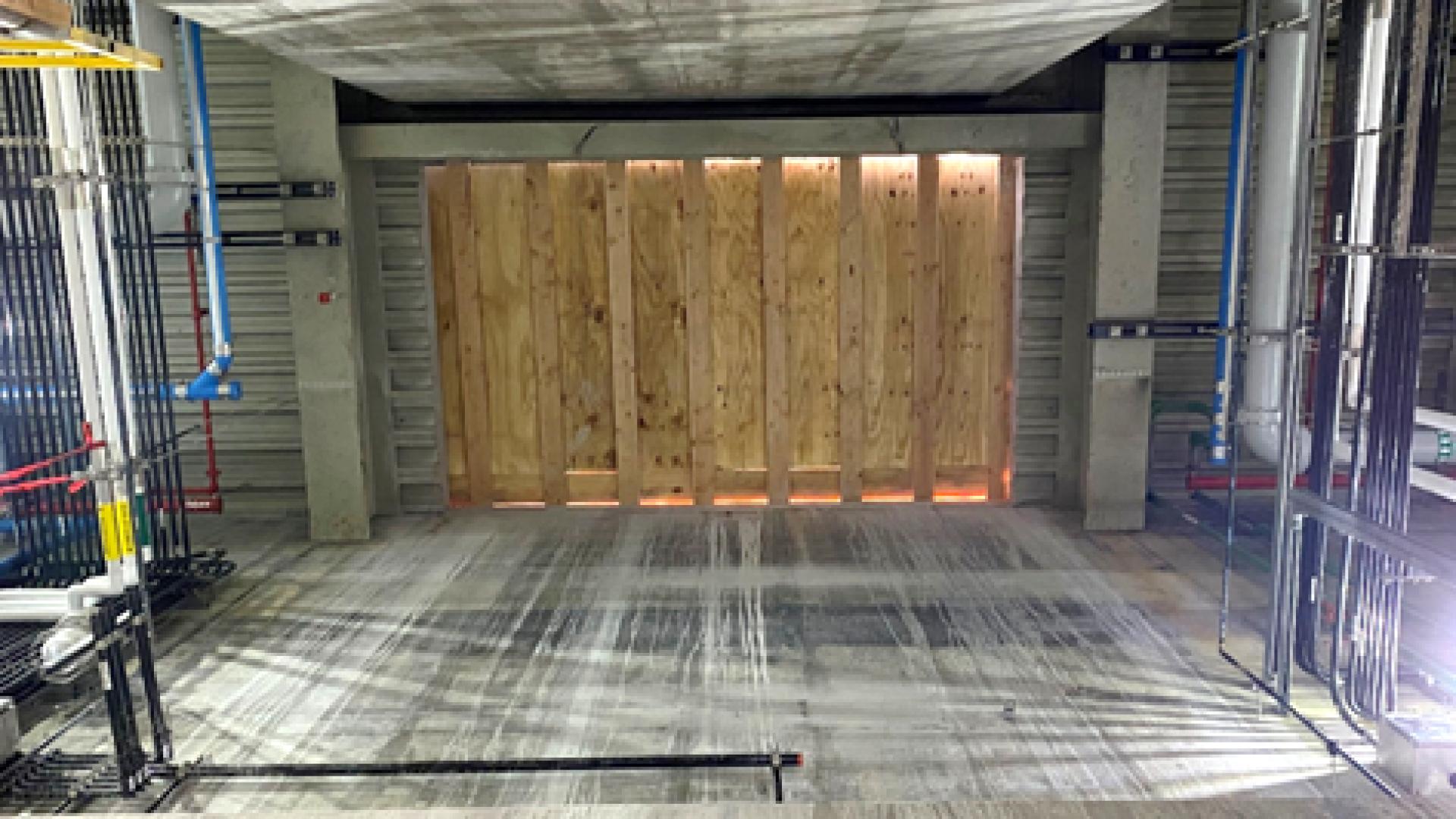

Odor Control roof with temporary removable panels over carbon adsorbers

Hot water piping in screen room in AHU-5 & 6

Previous 1 of Next Constructing stair 12 Masonry and tie into existing bench structure

Previous 1 of Next Odor Control Stainless FRP Duct

dor Control FRP Duct Installation

Wet Scrubber Rehab and Chemical Pumps

Odor Control Fan #2 (fan and damper controls)

AHU-3 & 4 rigging (Truck Bay hatch hoist)

Previous 1 of Next Odor Control Stainless Steel Duct Installation

Odor Control FRP Duct Installation

Wet Scrubber Rehab (Chevron Mist Eliminators, spray nozzles and media)

Stair 12 at ground level. Masons will begin building a stair tower.

Air Handler Replacement (AHU- 1 & 2) will serve pump and blower room

Previous 1 of Next Odor Control Duct Installation at Wet Scrubbers

Air Handler Replacement (Pump & Blower Room)

Previous 1 of Next Odor control fan #1 and 2 pads

Wet scrubber & 90-inch Duct Demo

Elevated walkway platform (access to dampers and controls)

8-inch Sanitary Ejector Piping

Previous 1 of Next New fuel oil tanks in service

Odor Control Fan Headers (new fan on left, old fan on right)

Caustic storage tanks and pumps

Previous 1 of Next Utility relocation at Stair 12 (Building code requires new egress path)

HVAC duct replacement in Grit Area

Underground fuel oil tank piping and wiring

Breeching for new boilers

Previous 1 of Next Setting one of the 20,000 Fuel Oil Storage Tanks

20,000 Gallon Underground Fuel Oil Storage Tanks in place

Odor control duct being rigged into the odor control room

Wet Scrubber #3 Inlet Duct fitup

Carbon absorber #1 demolition

Previous 1 of Next Temporary OC Duct (preliminary testing to test flow for changes)

Temporary Supply Air Fans

Excavation for new underground storage tanks

Previous 1 of Next Portable CAD Unit (ductwork outside)

Previous 1 of Next Fan 4 intake (suction) prior to installation of additional Odor Control Duct

Exhaust from fan 4 as it enters the header

Odor control room (future hypochlorite location)

Sub-contractor prep work to get fan up and running

New stainless steel ducts in grit level

Previous 1 of Next Odor Control Fan #4 set in place & grouting base frame

New Odor Control SCADA cabinet set in pump and blower room

New caustic tanks set in place

Chemical fill piping for sodium hypochlorite and sodium hydroxide

Temporary carbon absorber unit

HVAC duct work in screen room

Work at spillway, finishing grouting rails and planning stop logs

Previous 1 of Next Stop log frames being installed in the emergency spillway. There is a yellow crane hauling some logs.

Stop log frames being installed in the emergency spillway. Workers installing structures at spillway.

90-inch odor control fan header installed

Forms for new odor control dan foundation

Caustic storage tanks delivered and stored on site

Previous 1 of Next Temporary Ductwork at grit level

Temporary duct system to provide ventilation while existing ductwork gets replaced

Temporary fans to provide ventilation while air handlers get replaced

Outdoor roof and removable covers and ductwork being delivered to site

New 90-inch Odor Control Header being rigged into place

New odor control fans being shop tested to confirm operation

Previous 1 of Next 90-inch duct and dampers removed from odor control room

Sawcutting walls in Grit Room for temporary duct work

Temporary ductwork in Grit Room prior to replacing new ductwork

Sluice gates at emergency spillway that will be replaced

Portable operator to close spillway gates if power is lost.

Previous 1 of Next Demolition of sodium hypochlorite containment wall

Site of future sodium hydroxide (caustic) storage tanks and pumps

Ductwork from grit area to feed odor control room

Next month's work at emergency spillway stop logs and sluice gates

Previous 1 of Next Odor Control Roof with removable covers for equipment access to wet scrubbers and CAD-1

Temporary waterproofing at removable concrete planks on Odor Control Roof

Ductwork and heat exchanger below removable roof planks that will be demolished in Odor Control Room

Demolition of existing wet scrubber recirculation pumps

Electrical conduits installed in the Odor Control Room to power new equipment

Previous 1 of Next Contractor establishing work zone with concrete barriers, fences and screens at the Odor Control Roof

Contractor removing soil from Odor Control Roof

Location of new odor control fan that will replace the fan that was damaged in the 2016 fire

Previous 1 of Next