MWRA turned on the MetroWest Water Supply Tunnel in November 2003.

The new tunnel greatly enhances the security, capacity and reliability of MWRA's entire water transmission system.

Until now, MWRA has relied on a single 1940's-era surface aqueduct, the Hultman Aqueduct, to serve all of Metro Boston. With its leaks and

aging valves, the Hultman needed to be taken off-line for major repairs.

Before the MetroWest Tunnel, failure of the Hultman could have caused nearly complete interruption of Boston's water supply. This would have been a disaster for the region's public health, safety and economy.

Purpose: | To enhance the security, capacity and reliability of the water system that serves 2.3 million people in 40 communities |

Total Program Budget Set in 1995: | $728 million |

Total Program Estimated Completion Costs: | $665 million (includes design, construction management, construction |

Awarded construction: | 8 contracts valued at over $506 million in construction costs |

Length of tunnel: | 17.6 miles – roughly the distance from Rte. 495 to Rte 128, parallel to the Mass. Turnpike |

Diameter: | Mined at 16 feet, finished at 14 feet |

Depth: | 200-500 feet deep |

Years to Complete each phase of construction: | Excavating Shafts: 1 year Mining: 2 years Lining: 2 years Line Shafts: 1 year Piping, connections and disinfection: 1 year |

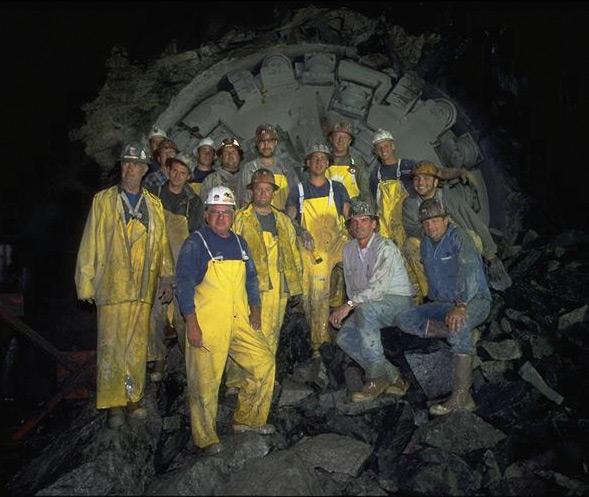

Construction schedule and duration: | Construction work took place over a 7-year period with over 6 million man-hours worked. Work proceeded 24 hours per day on 3 shifts, 5-6 days per week with no fatalities. |

Mining: | 3 machines, each valued at over $7 million, were used to mine the tunnel 3 major working shafts: (Southborough, Framingham and Weston) 9 connections to water facilities and communities |

Under five communities: | Marlborough, Southborough, Framingham, Wayland, and Weston Wye intersection 235 feet below the Mass. Turnpike tolls at Rte. 128 |

Average production rate: | 57.1 feet per day |

Total rock excavated: | 1, 025,000 cubic yards |

Kinds of Rock Excavated: | Granite, gneiss, shist, quartzite and others |

Total Amount of Concrete Used for Lining: | 184,722 cubic yards |

Concrete Production Rate: | 154 cubic yards per day |

Average production for lining: | 77 lineal feet per day |

Project coordinated with: | Treatment Facilities at Walnut Hill (Marlborough) and Covered Storage at Norumbega |

Amount of water needed to fill the tunnels and shafts: | 105.5 million gallons |

Disinfected with: | 42,000 gallons of sodium hypochlorite (chlorine) |

Total Number of People Who Worked on the Project: | 1,907 |

Maximum Number of People Working at One Time: | 598 |

Unions on the Job: | Tunnel Workers Local 88, Operators Local 4, Electricians Locals 103 and 96 |

Schedule: | Broke Ground late 1996 Finished construction on schedule in Spring 2003 Final Testing and Disinfection in Summer/early Fall 2003 |

Memorandums of Agreement with Communities: | Weston Wayland Framingham Southborough |

Designers: | Sverdrup/Jacobs Civil Inc. |

Construction Management Team: | Stone and Webster Massachusetts Inc., a Shaw Group Co. Parsons Brinckerhoff Construction Services Inc. Regina Villa Associates Hager GeoScience H2O Engineering Consulting Assoc. DMC Engineering Judith Nitsch Engineering Revet Environmental |

Major Contractors: | Shea/Traylor/Healy Modern Continental/Obayashi Barletta Heavy Division |

Contact Us

*This project was completed in 2003 and is considered to be archived.*

If you have questions or concerns about this project, please e-mail AskMWRA@mwra.com.